Services

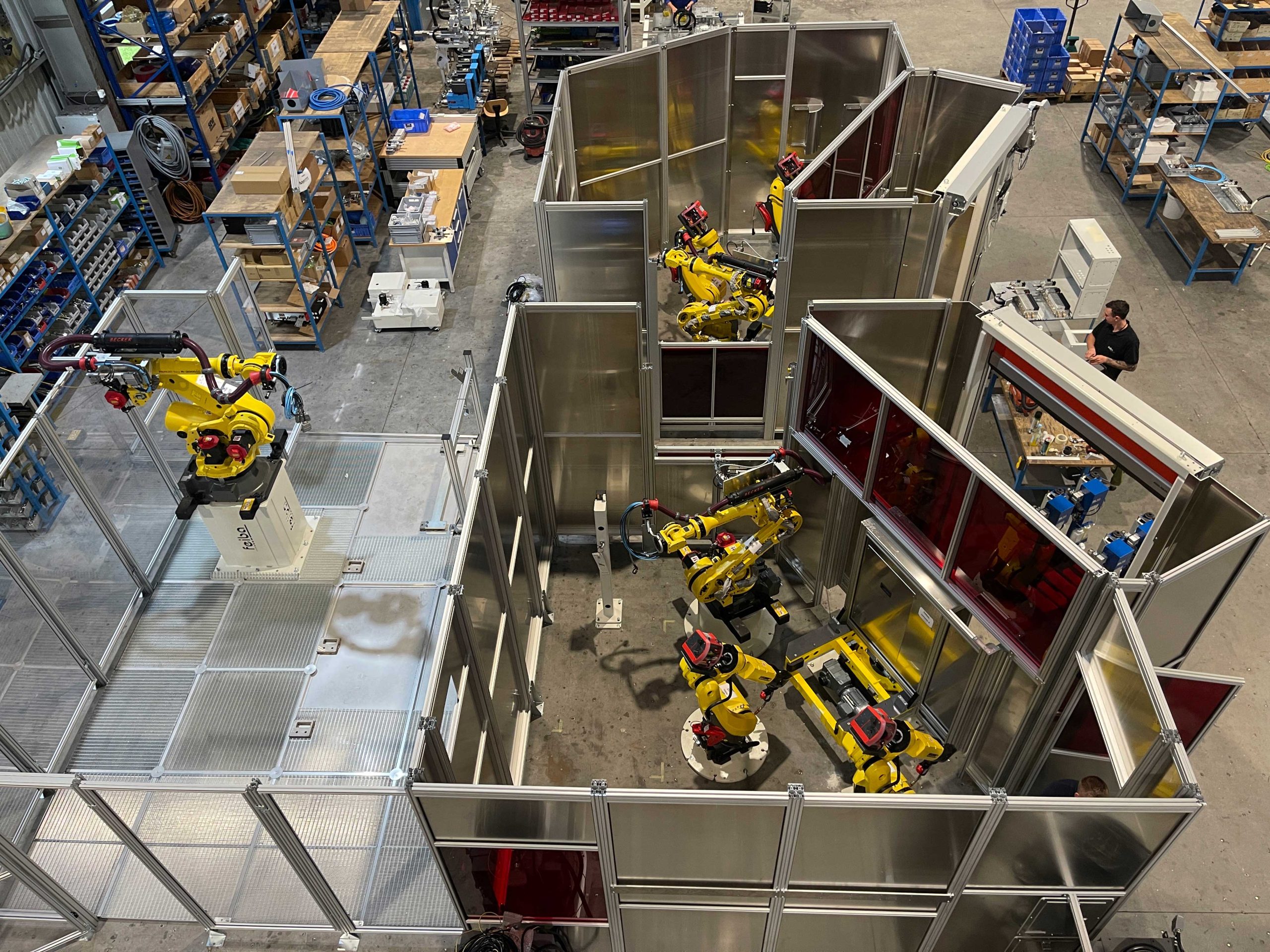

Automated systems for joining components

We are a full-service provider, essentially acting as a general contractor– for planning and implementing (fully) automated production lines, especially for joining aluminum and steel components:

- Planning – we develop your ideas!

- 3D-design & simulation – we create your ideas!

- Manufacturing and assembly – we build your ideas!

- Automation – we implement your ideas!

Based in Upper Austria, we supply for the Central European market. Furthermore, we have also successfully realized projects in the USA.

Production cells

Rebuilding

(including other prior providers)

cell & line modifications for new parts

Meeting the requirements for joining components has increasingly become more demanding. This is in part due to the combination of several different production technologies

in a single component.

With Feiba, it is possible to integrate a wide range of different joining processes within one production plant – including testing and marking stations – no matter what brand of robots you choose! We are furthermore happy to integrate already existing systems/machines in your facility.

Together we will find the ideal concept for you.

- Individual cells for variable manufacturing concepts or linked and flexibly convertible facilities

Your benefits:- many different components possible in one cell

- save space in the factory

- produced quantities can be adapted to demand

- save costs as the cell is in “continuous operation”

- programming per component incl. coding/plug assignment for the safety of your production workers

- fixture construction

- gripper systems

We live affinity to ENGINERING – to achieve the best for you!

Automated applications in our portfolio

- Welding incl. seam tracking: Laser welding, MIG-/MAG welding, spot welding, nut welding, projection welding, stud welding, TIG-welding, plasma welding…

- Blanking & press in operations: blind rivet nut application, flow-drill-screwing (FDS), self-pierce rivets application, press in bolts – and nuts application, hole blanking, screwing …

- Adhesive application: various types of adhesive applications (stationary or robot mounted solutions) 1C,2C, …

- Coating: Application of flame protection

- Fuel tank welding:

- Roll hemming applications

- Marking stations

- Clinching

- Helicoil thread inserts applications

Here, we are second to none!

- Fixture construction / manufacturing

- Manipulating systems: small- & lightweight parts, powertrain products, steel production

- Robot – & PLC- programming

New Technologies? Prototypes? New Ideas?

We are happy to advise and support you!